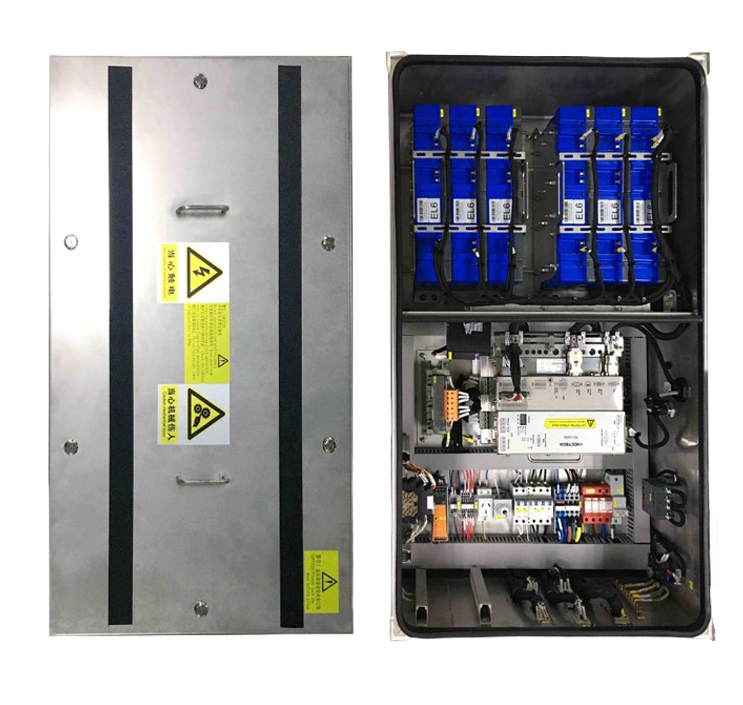

Yaw Drive (S610)

*Customized software solutions according to customer requirements

Why Your Yaw System Need a Yaw Drive?

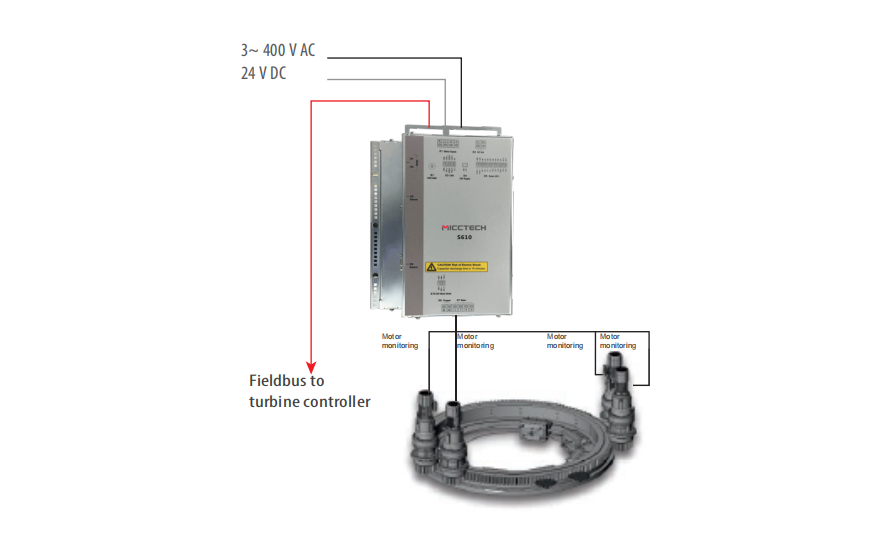

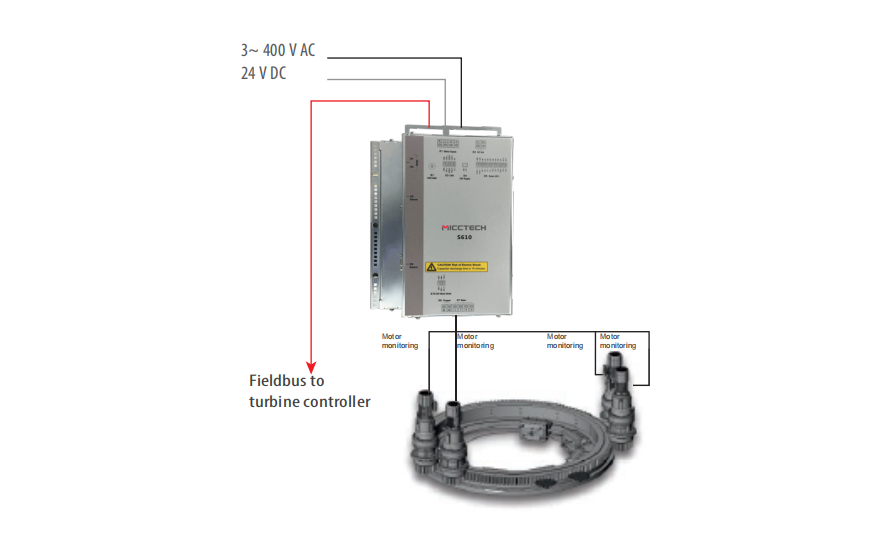

Conventional grid-connected yaw motors exhibit critical technical shortcomings - direct switching creates damaging inrush currents that accelerate mechanical wear, while traditional yaw systems suffer from excessive failure rates and inadequate wind alignment accuracy. MICCTech S600 yaw drives can overcome these limitations and have been successfully applied to nearly 10,000 wind turbines.

Gear Protection & Cost Reduction

- Prevents gear wear caused by direct grid connection during motor startup

- Extends gear service life to 20+ years (maximum)

- Reduces O&M costs by 30-40%

- Minimizes wind alignment errors(<0.5°)

- Activates turbulence protection mode under unstable wind conditions

- Built-in monitoring system with real-time remote comms

- Comprehensive fault protection including:

✓ STO (Safe Torque Off)

✓ SBC (Safe Brake Control)

Key Features of S610

Control Program

Dual drive control with ns level

communication delay

Quick Start

Adopting half-control rectification scheme to avoid power grid impact and realize power-on soft start

Safety

Slury solutions for emergencies

Fault Storage

Support for Failed Snapshot Storage

Easy Maintenance

With visualization interface

Wide Busbar Operating Range

150V-180V DC

Wind Turbine Components from MICCTech

Since 2014, MICCTech has been providing professional products and technical services for onshore and offshore wind turbine solutions, with over 20,000 units installed globally.

Leveraging independently developed technologies and components, MICCTech's products are highly recognized by customers for their exceptional reliability, even under extreme environmental conditions.

Our knowledgeable team is ready to meet your needs in pitch control systems, yaw drive systems, and after-sales services.

For maintenance, spare parts, or retrofit operations, our technical experts offer professional advice and top-tier support.

MICCTech--Smarter Choice for You!

As of today, MICCTech has already partnered with many renowned brands, such as Goldwind, Windey, Mingyang, CRRC, and CSIC, to provide them with product substitution and technological upgrading services.

MICCTech's Pitch Drives and Yaw Drives are highly integrated. For example, they feature a built-in backup power charger, which further reduces the number of components in the cabinet, maximizing availability and ease of maintenance.

Additionally, they are highly reliable and suitable for installation at elevations of up to 6,000 meters, with an operating temperature range of -40°C to +70°C inside the cabinet.

Why Your Yaw System Need a Yaw Drive?

Conventional grid-connected yaw motors exhibit critical technical shortcomings - direct switching creates damaging inrush currents that accelerate mechanical wear, while traditional yaw systems suffer from excessive failure rates and inadequate wind alignment accuracy. MICCTech S600 yaw drives can overcome these limitations and have been successfully applied to nearly 10,000 wind turbines.

Gear Protection & Cost Reduction

- Prevents gear wear caused by direct grid connection during motor startup

- Extends gear service life to 20+ years (maximum)

- Reduces O&M costs by 30-40%

- Minimizes wind alignment errors(<0.5°)

- Activates turbulence protection mode under unstable wind conditions

- Built-in monitoring system with real-time remote comms

- Comprehensive fault protection including:

✓ STO (Safe Torque Off)

✓ SBC (Safe Brake Control)

Key Features of S610

Control Program

Dual drive control with ns level

communication delay

Quick Start

Adopting half-control rectification scheme to avoid power grid impact and realize power-on soft start

Safety

Slury solutions for emergencies

Fault Storage

Support for Failed Snapshot Storage

Easy Maintenance

With visualization interface

Wide Busbar Operating Range

150V-180V DC

Wind Turbine Components from MICCTech

Since 2014, MICCTech has been providing professional products and technical services for onshore and offshore wind turbine solutions, with over 20,000 units installed globally.

Leveraging independently developed technologies and components, MICCTech's products are highly recognized by customers for their exceptional reliability, even under extreme environmental conditions.

Our knowledgeable team is ready to meet your needs in pitch control systems, yaw drive systems, and after-sales services.

For maintenance, spare parts, or retrofit operations, our technical experts offer professional advice and top-tier support.

MICCTech--Smarter Choice for You!

As of today, MICCTech has already partnered with many renowned brands, such as Goldwind, Windey, Mingyang, CRRC, and CSIC, to provide them with product substitution and technological upgrading services.

MICCTech's Pitch Drives and Yaw Drives are highly integrated. For example, they feature a built-in backup power charger, which further reduces the number of components in the cabinet, maximizing availability and ease of maintenance.

Additionally, they are highly reliable and suitable for installation at elevations of up to 6,000 meters, with an operating temperature range of -40°C to +70°C inside the cabinet.

Technical Specification

Yaw Drive (S610)

Product Inquiry

Tell us your project requirements, our engineering team is ready to assist you. Your information will be 100% confidential.

Related Products

+ PT100 temperature detection+ Charger+ EMC filters

*Customized software solutions according to customer requirements

*Support customer self-configuration of product features

Pitch Control System (from 1.5-18mW)

* Applied to 1.5~ 18mW low temperature, plateau and offshore wind turbines

* 20 years long service life

*Customized software solutions according to customer requirements

WeChat:+86 158 7163 8792

WhatsApp:+86 19068019792

Tel:+86 158 7163 8792

Email:sales.global@micctech.com